Behind the Curtain: A Tour of General Motors and How Car Safety Is Designed

Our Up Close and Personal Look at Development and Innovation at General Motors’ Michigan Campus.

It’s just mind-boggling to think about what is in a car these days: 10,000 parts; 35 or more computers; car safety systems that do everything from shifting the car’s weight with changes in the weather to a tiny motor that tightens your seatbelt to a voice-activated system that will play your favorite songs or call your sister. Who at General Motors comes up with all that?

Here we are inside the GM wind tunnel–the largest in the US. We are standing next to the fan blade that when it rotates at creates the wind.

We got a tour of the General Motors campus in Warren, Michigan, right outside of Detroit, and saw not just how the company is leading in the development of women in top jobs, but also how the company is focused on its customer for new and better ideas. It’s there, in this mini-city of buildings, that GM develops and innovates its cars and systems. We were able to talk to number of engineers and designers and learn the detailed thinking and planning that focuses on the automaker’s goals: function, car safety and improvements.

Specifically, we toured three areas that show how the automaker works to deliver to customers what they want: fuel efficiency, safety and comfort.

Fuel Efficiency: Weight Loss = Better Gas Mileage

One of the major reasons cars are more fuel efficient these days is weight: lose weight, use less gas. To make cars and trucks lighter, many manufacturers are using lighter weight materials, including aluminum. But the process of building with aluminum required rethinking how a car is designed, welded and assembled.

At GM’s Warren center, the team came up with not only new ways to weld (not involving flame and a blow torch!) but also techniques that can be performed by robots in the assembly plant.

Aerodynamics = Better Gas Mileage

Every girl knows this: If you want resistance, don’t shave your legs. You’ll feel the resistance when you put on your favorite tights. So it’s no accident that airplanes have a pointed front end; that allows the plane to pierce the air in front of it and move through with as little resistance as possible.

Similar thinking goes into cars: Design teams use clay models and small-scale models to develop prototypes of new cars and wind test them in the center’s wind tunnel.

They even think of how the wind will flow over door handles and under the car, and where air flow might slow a car down, forcing it to use more fuel to reach and maintain speed on the road.

Safety Check: Crash Test Dummies

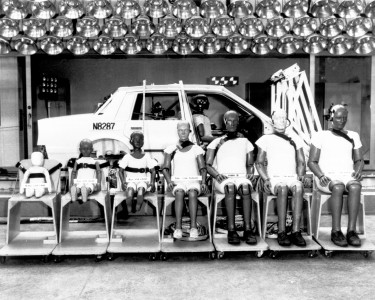

You’ve probably seen the crash test dummies that auto companies use to safety test their cars; they’ve starred in TV ads and been adapted for all sorts of things that can affect human safety. But what we didn’t know is the depth of development that the ‘dummies’ have undergone: GM, which developed some of the first test dummies, or anthropomorphic test devices as they are known in the research world, has helped to set and raise government standards on safety testing, and had extended the line of dummies used from a few basic ones to more than 2,000, and more than 8,500 different tests are conducted with them.

To continually develop the crash test dummies, GM works closely with the trauma center at the University of Michigan Hospital emergency room to investigate.

Brake Testing

Here’s what I think brakes do: you put your foot on the brake and a force is applied to the wheels to make them stop moving.

Here’s what really happens: you put your foot on the brake and it transmits to an already active traction and control system the speed of braking that needs to occur; this information is fed out to each wheel’s independent systems and then back to shift weight, speed and apply traction to each wheel in proportion to the amount of stopping resistance needed, determined by speed of the vehicle, ideal stopping distance and obstacles that the car senses in its path, all while keeping the vehicle safe and hopefully, out of an accident.

Not what you see on your ten speed bike, is it?

Much of a car’s safety system is built into the brake and traction function, so it’s where a lot of GM’s innovation and testing focuses.

But here’s what is surprising: like a chef obsessed with perfecting the perfect souffle, the brake team takes innovative, great-functioning systems and applies new information, circumstances and criteria to anticipate what function they will need next and how these systems can make cars even safer.

Comfort: Not Just What’s Under Your Tush

Yes, a nicely crafted seat and leather armrests are comfortable. But how a car is engineered is key to comfort, too. Among the things we observed at the GM center that determine a comfortable ride are:

A 2014 GMC Sierra pickup undergoes testing in the GM Aerodynamics testing. Time spent in the lab led to advancements in body design and sealing.

Road Noise

Testing for this starts in the wind tunnel, where engineers can tell how well insulated and sealed the car is from wind, which creates noise while you’re on the road.

Vibration

If components on a car are knocked around by the wind, the car may shake and rattle. Fun on a roller coaster, but not on the 405.

Brake noise

Here are those all-important brakes again. Brake squeaking is inherent to the process; but it’s also like fingernails on a chalkboard. Noise reduction is a constant effort so you never hear the sound of brakes squealing, even though if you do, it’s probably a sign of normal wear and good performance.

Roughness

Also in the brake lab, testing for roughness is done; stopping can be a rough experience or a smooth one, and they are shooting for smooth. They test how well systems bring a vehicle to a smooth stop.

I was General Motors’ guest at the company’s Michigan Campus, and GM accommodated my travel. During my experience I was able to ask questions, listen to experts and further my expertise on cars.